PP reaction tank introductionXinhanze

PP reaction tank is a chemical container made of polypropylene (PP) as raw material, which is widely used in many fields with its excellent performance. The following is a detailed description of it:

1. Material properties

Polypropylene material gives the reaction tank excellent chemical resistance, strong resistance to acid and alkali and other chemical media, not easy to aging, and has a certain heat resistance (general temperature range -10 ℃ to 100 ℃), can adapt to a variety of chemical reaction conditions. At the same time, the material is non-toxic, tasteless, in line with health standards, suitable for cleanliness requirements of the environment.

2. Structural design

It is usually a cylindrical container, and the top can be equipped with a stirring device (as shown in the figure) to ensure uniform mixing of materials; it is equipped with a feed port, a discharge port, an observation port, etc., to facilitate material addition, discharge and reaction process monitoring. Some reaction tanks will also be equipped with thermometers, level gauges and other accessories to accurately control the reaction conditions.

3. Application areas

Widely used in chemical, pharmaceutical, food, environmental protection and other industries, can be used for acid-base neutralization, polymerization, material dissolution and other processes, such as chemical raw material synthesis, drug intermediate reaction, food additive preparation.

1. Material properties

Polypropylene material gives the reaction tank excellent chemical resistance, strong resistance to acid and alkali and other chemical media, not easy to aging, and has a certain heat resistance (general temperature range -10 ℃ to 100 ℃), can adapt to a variety of chemical reaction conditions. At the same time, the material is non-toxic, tasteless, in line with health standards, suitable for cleanliness requirements of the environment.

2. Structural design

It is usually a cylindrical container, and the top can be equipped with a stirring device (as shown in the figure) to ensure uniform mixing of materials; it is equipped with a feed port, a discharge port, an observation port, etc., to facilitate material addition, discharge and reaction process monitoring. Some reaction tanks will also be equipped with thermometers, level gauges and other accessories to accurately control the reaction conditions.

3. Application areas

Widely used in chemical, pharmaceutical, food, environmental protection and other industries, can be used for acid-base neutralization, polymerization, material dissolution and other processes, such as chemical raw material synthesis, drug intermediate reaction, food additive preparation.

PP SiloXinhanze

1. Material properties

PP silo is made of polypropylene, this material has excellent chemical resistance, can effectively resist the erosion of acid and alkali and other chemical media, and has a certain heat resistance (the use of temperature range is usually -30~140 ℃), not easy to aging, while the material is light, easy to install and transport.

2. Functional use

Mainly used in chemical, corrosive places, plastic processing and other industries, bear the material storage and mixing function. For example, in a PP plant, different batches of raw materials can be stored and mixed to ensure the uniformity of the chemical reaction, thereby ensuring product quality. The blending bin in the spherical graphite project is used to store and mix raw materials and is a key equipment in production.

PP silo is made of polypropylene, this material has excellent chemical resistance, can effectively resist the erosion of acid and alkali and other chemical media, and has a certain heat resistance (the use of temperature range is usually -30~140 ℃), not easy to aging, while the material is light, easy to install and transport.

2. Functional use

Mainly used in chemical, corrosive places, plastic processing and other industries, bear the material storage and mixing function. For example, in a PP plant, different batches of raw materials can be stored and mixed to ensure the uniformity of the chemical reaction, thereby ensuring product quality. The blending bin in the spherical graphite project is used to store and mix raw materials and is a key equipment in production.

Package PTFE stirring paddleXinhanze

1. Material characteristics

PTFE has excellent chemical stability, almost no acid, alkali, salt and organic solvent corrosion, high and low temperature resistance performance, can be used for a long time in the range of -180 ℃ ~ 200 ℃, and the surface is smooth, non-sticky, not easy to adhere to the material, with self-lubricating.

2. Structure composition

Rod body: usually with iron rod as the base body, external cladding PTFE layer, taking into account the strength and corrosion resistance, reduce costs.

Blades and other components: the use of pure PTFE material, to ensure that the material contact part of the corrosion resistance.

3. Product features

Corrosion resistance: excellent resistance to strong acid and alkali, organic solvents, etc., suitable for corrosive medium stirring.

Flexible design: some products are equipped with foldable paddles, which is convenient for the use of small bottle mouth containers. The crescent-shaped design fits the curved bottom container and stirs more fully.

High efficiency: suitable for medium and high speed mixing of low viscosity fluid, high mixing efficiency.

Strong anti-permeability: high density PTFE sheet, coated with PTFE layer can effectively prevent the penetration of the medium, prolong the service life.

PTFE has excellent chemical stability, almost no acid, alkali, salt and organic solvent corrosion, high and low temperature resistance performance, can be used for a long time in the range of -180 ℃ ~ 200 ℃, and the surface is smooth, non-sticky, not easy to adhere to the material, with self-lubricating.

2. Structure composition

Rod body: usually with iron rod as the base body, external cladding PTFE layer, taking into account the strength and corrosion resistance, reduce costs.

Blades and other components: the use of pure PTFE material, to ensure that the material contact part of the corrosion resistance.

3. Product features

Corrosion resistance: excellent resistance to strong acid and alkali, organic solvents, etc., suitable for corrosive medium stirring.

Flexible design: some products are equipped with foldable paddles, which is convenient for the use of small bottle mouth containers. The crescent-shaped design fits the curved bottom container and stirs more fully.

High efficiency: suitable for medium and high speed mixing of low viscosity fluid, high mixing efficiency.

Strong anti-permeability: high density PTFE sheet, coated with PTFE layer can effectively prevent the penetration of the medium, prolong the service life.

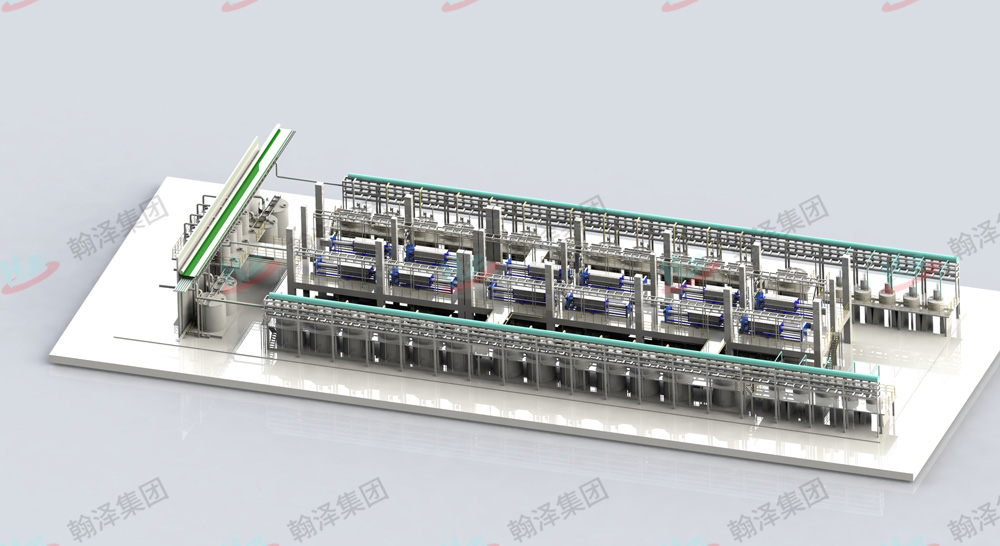

PP flotation cellXinhanze

1. Material properties

Polypropylene material, with excellent resistance to chemical corrosion, can resist the erosion of strong acid, alkali and other media, can work stably in complex chemical environment, long service life.

2. Working principle

By introducing bubbles, the target mineral particles or materials are attached to the surface of the bubbles, and then float to the liquid surface to form a foam layer to achieve separation from other substances, which is suitable for mineral sorting, chemical raw material purification and other scenarios.

3. Structure and characteristics

Compact structure: scientific design, small footprint, easy installation and layout.

Lightweight and easy to maintain: light weight, convenient handling and installation; strong corrosion resistance, reducing maintenance frequency and cost.

Cost advantage: Compared with metal flotation tank, PP flotation tank has lower manufacturing cost and high cost performance.

Polypropylene material, with excellent resistance to chemical corrosion, can resist the erosion of strong acid, alkali and other media, can work stably in complex chemical environment, long service life.

2. Working principle

By introducing bubbles, the target mineral particles or materials are attached to the surface of the bubbles, and then float to the liquid surface to form a foam layer to achieve separation from other substances, which is suitable for mineral sorting, chemical raw material purification and other scenarios.

3. Structure and characteristics

Compact structure: scientific design, small footprint, easy installation and layout.

Lightweight and easy to maintain: light weight, convenient handling and installation; strong corrosion resistance, reducing maintenance frequency and cost.

Cost advantage: Compared with metal flotation tank, PP flotation tank has lower manufacturing cost and high cost performance.

PP tail gas treatment equipmentXinhanze

PP tail gas treatment is a process of purifying the tail gas generated in industrial production, aiming at removing harmful components, making it meet environmental emission standards and reducing environmental pollution. The treatment often with the help of PP tail gas absorption tower and other equipment, these equipment with polypropylene (PP) as the material, strong corrosion resistance, suitable for chemical, electronics, metallurgy and other industries of waste gas treatment.

Selected field cases

Carbon nanotube purification production line

Fujian, China

Anode Materials for Sodium Batteries

Overseas project site

Indonesia

Unknown

Recycled negative material purification production line

Anhui, China

Recycled negative material

Expandable graphite production line

China

expandable graphite

Natural purification production line

China

natural graphite

Sodium-Hard Carbon Purification Line

Fujian, China

nano battery

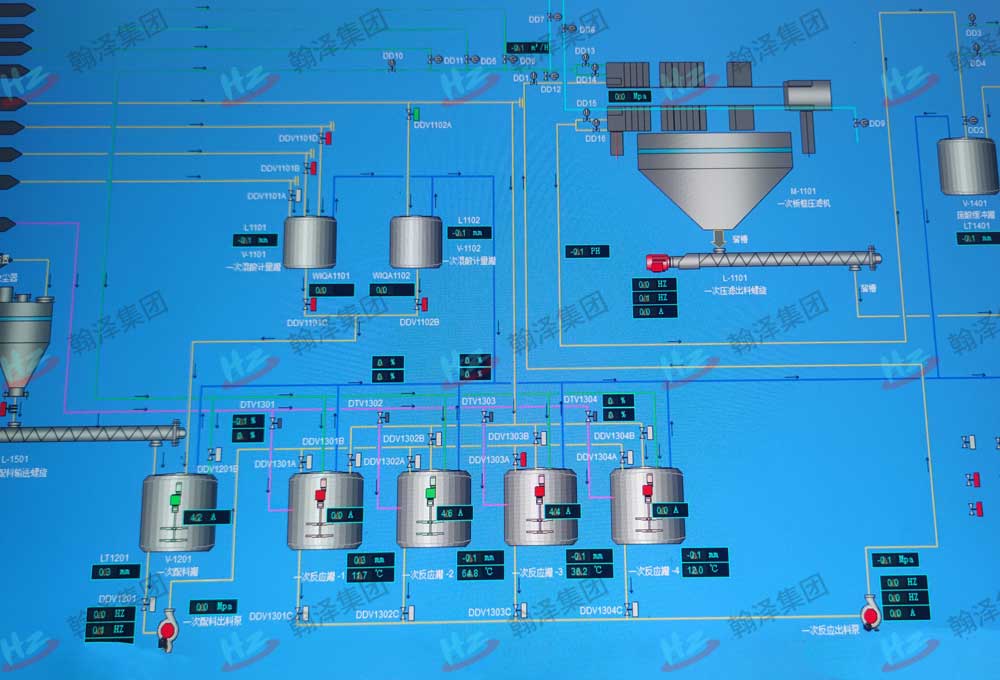

automatic control system

China

Unknown

porous carbonic acid washing production line

China

porous carbonic acid washing

Quartz sand pickling production line

China

Quartz sand pickling

PPH Equipment

China

PP Equipment