Main impurities and hazardsXinhanze

Hazards: The presence of impurities will affect the chemical stability, fire resistance, insulation and other properties of quartz sand. For example, iron impurities will change the color of quartz sand at high temperatures, reduce its whiteness and purity, and affect its application in high-end fields such as optical glass and electronics.

Common purification methodsXinhanze

Magnetic separation: the use of different mineral magnetic differences, in the magnetic field under the action of magnetic impurities and quartz sand separation, can effectively remove iron, titanium and other magnetic minerals.

Flotation: according to the different wettability of mineral surface, adding suitable flotation reagent, so that the purpose of mineral attached to the bubble floating, and stay in the slurry of quartz sand separation, commonly used to remove feldspar, mica and other aluminum silicate minerals.

Acid leaching: the use of acid and impurities chemical reaction, the metal oxide and other impurities dissolved, after filtration, washing and other operations to remove impurities, can significantly improve the purity of quartz sand.

Process flowXinhanze

Then scrubbing desliming, magnetic separation and other steps are carried out in turn to initially remove most of the impurities.

For products with high purity requirements, deep purification treatment such as flotation and acid leaching will also be carried out.

Finally, after filtering, drying and other processes, high purity quartz sand products are obtained.

In actual production, according to the nature of quartz sand ore, impurity content and product quality requirements, optimize the process, select the appropriate purification methods and equipment, in order to achieve efficient and economic purification effect.

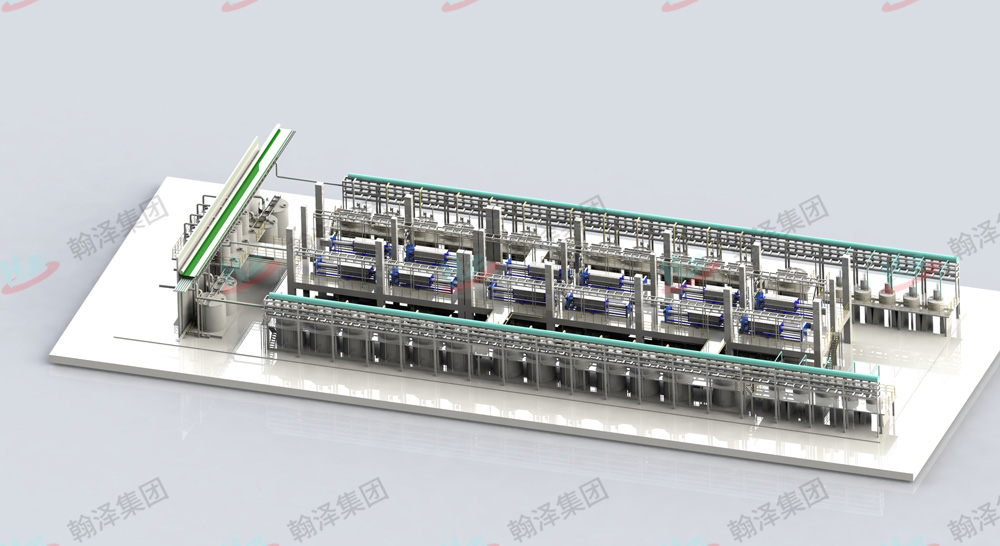

Construction site pictureXinhanze

Full-cycle worry-free service

01

Professional answers to customer inquiries

7*24 hours online service

02

Tailored Solutions

Solution within 2 hours

03

Assist in the preparation of construction plans

12 hours to the customer site

04

Guide installation and commissioning

Resolve operational issues within 24 hours

Selected field cases

Carbon nanotube purification production line

-

Fujian, China

-

Anode Materials for Sodium Batteries

Overseas project site

-

Indonesia

-

Unknown

Recycled negative material purification production line

-

Anhui, China

-

Recycled negative material

Expandable graphite production line

-

China

-

expandable graphite

Natural purification production line

-

China

-

natural graphite

Sodium-Hard Carbon Purification Line

-

Fujian, China

-

nano battery

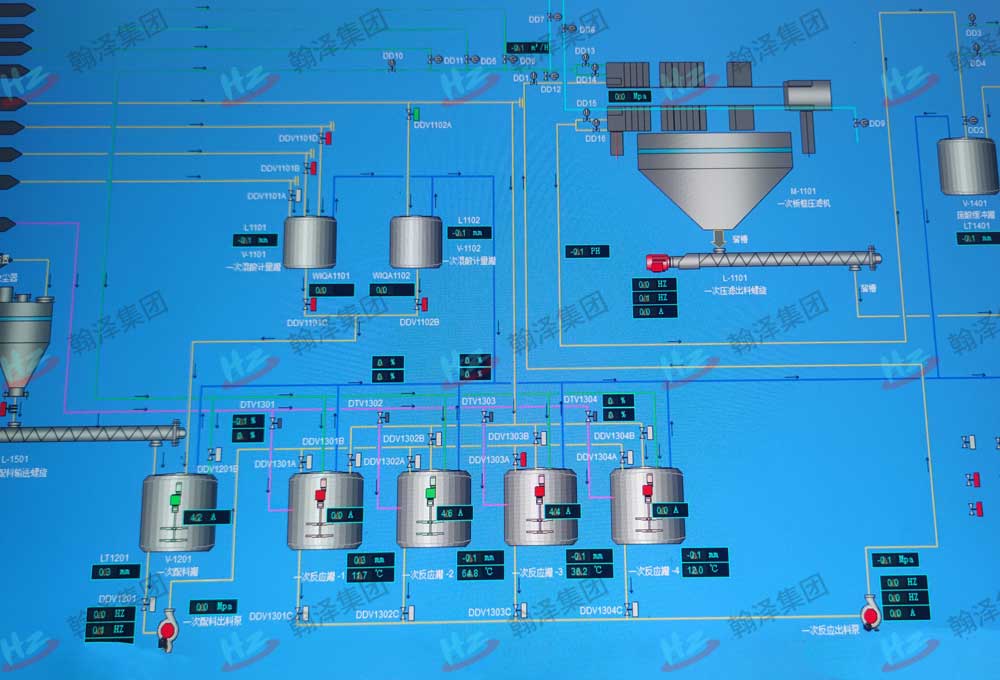

automatic control system

-

China

-

Unknown

porous carbonic acid washing production line

-

China

-

porous carbonic acid washing

Quartz sand pickling production line

-

China

-

Quartz sand pickling

PPH Equipment

-

China

-

PP Equipment