Deep Integration of 5G Industrial Internet of ThingsXinhanze

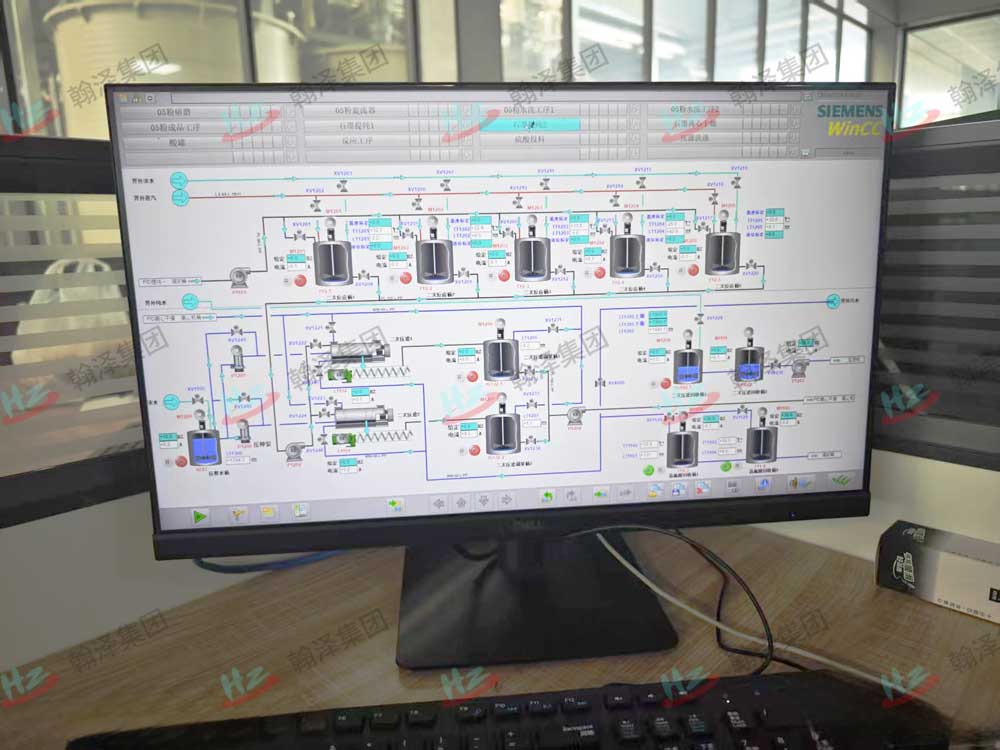

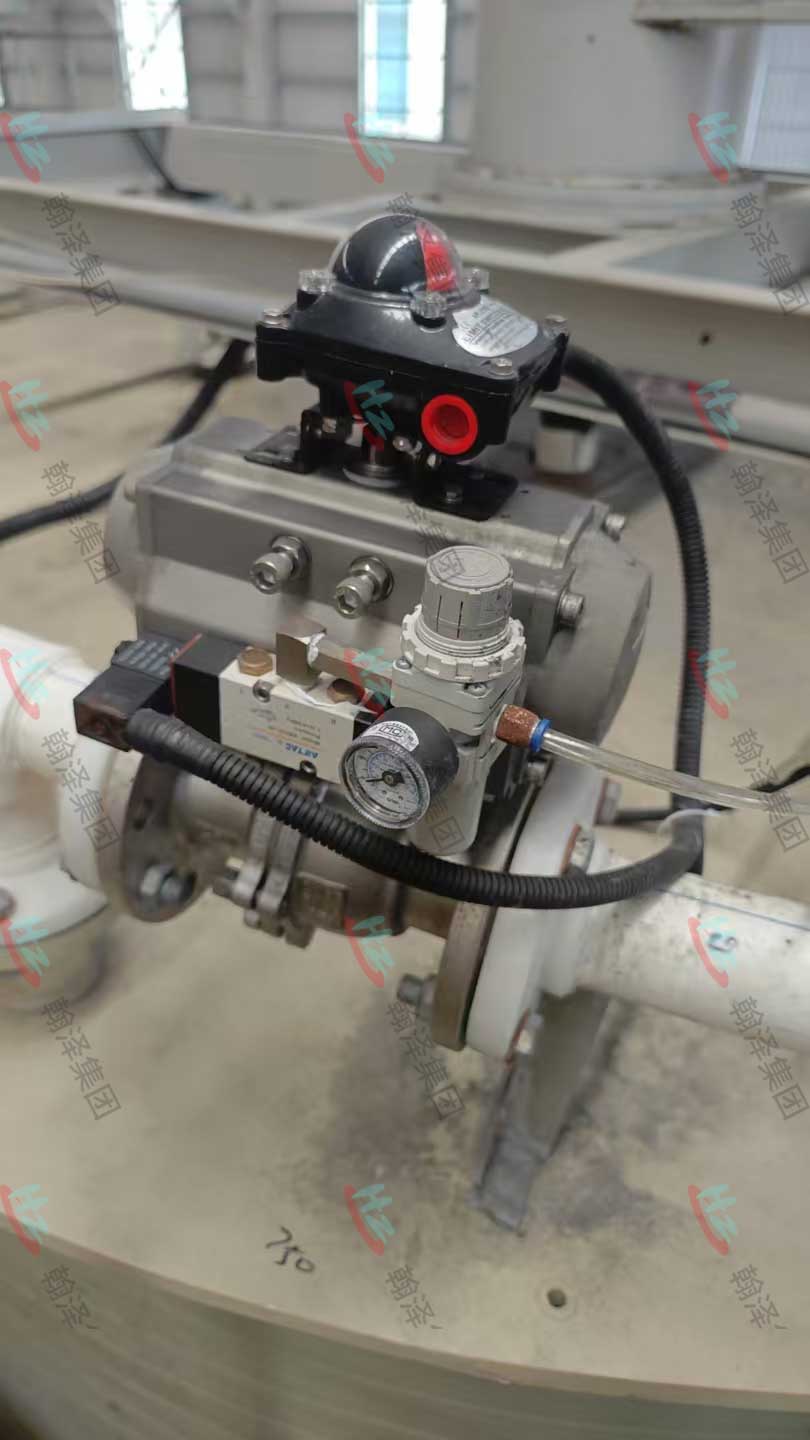

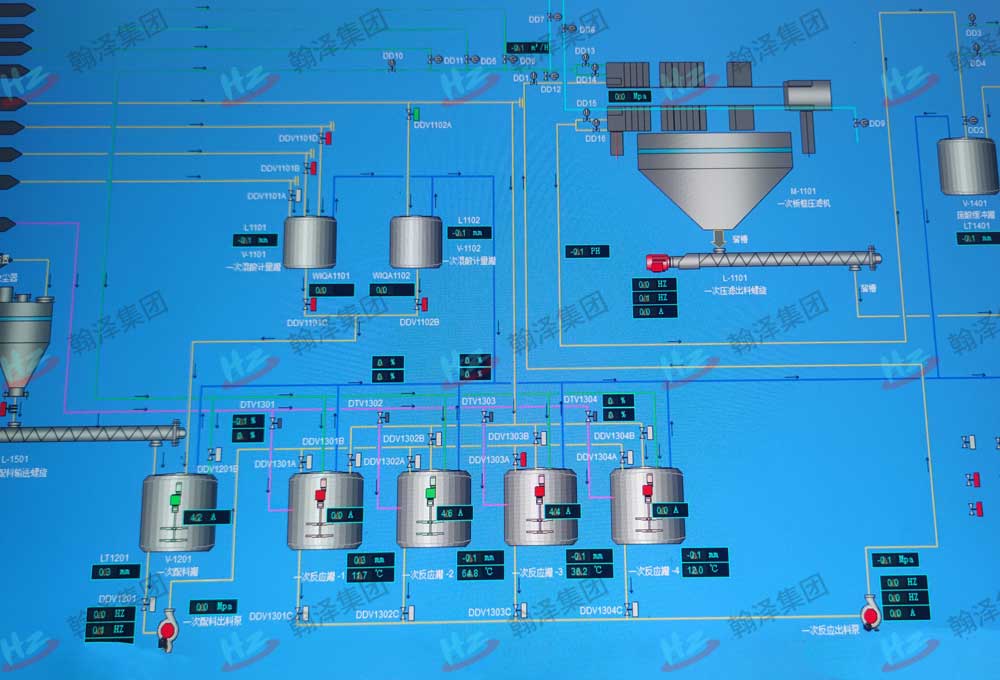

Full process automation control systemXinhanze

1. Intelligent batching: through the linkage of the Internet of Things weighing system and ERP system, the raw material ratio accuracy reaches +/-0.1, and manual intervention is reduced by 90%.

2. Reactive intelligent temperature control: 5G wireless temperature sensor is deployed, and heating curve is dynamically adjusted in combination with PID algorithm, energy consumption is reduced by 18%, and product consistency is improved by 25%.

3. Intelligent storage: AGV car is equipped with 5G positioning module to realize automatic material handling and improve logistics efficiency by 40%.

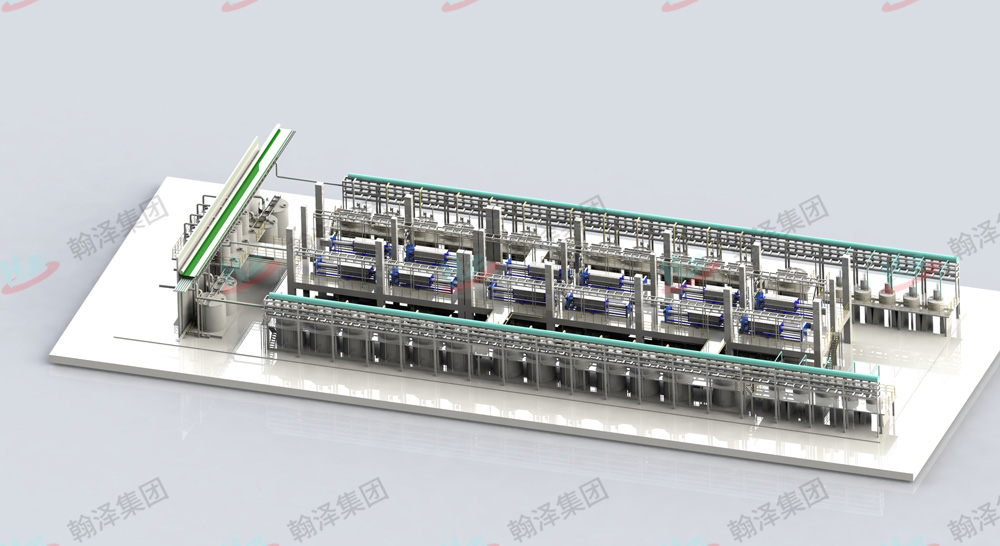

Digital Twins and Predictive Maintenance

Build a production line digital twin model to map the running status of physical equipment in real time. For example, through the spectral analysis of the vibration data of the roller press bearing, the accuracy of predicting equipment failure is 92%, and the maintenance cost is reduced by 35%. The technology has been applied to the Bertrand Group's 80000-ton anode material project in Indonesia, reducing equipment downtime by 60%.

Production efficiency jumpsXinhanze

2. Comprehensive efficiency optimization: Through the intelligent scheduling system, the OEE (comprehensive efficiency) of the equipment is increased from 65% to 82%, and the annual production capacity is increased by 30%.

Significant cost optimizationXinhanze

2. Energy consumption cost: through real-time monitoring of the energy management system, the power consumption per unit product is reduced from 850kWh to 680kWh, saving 2.6 million yuan per year.

3. Cost of quality: The rate of defective products decreased from 3.2 per cent to 0.8 per cent, reducing the annual loss of quality by more than 5 million yuan.

Safety and environmental upgradeXinhanze

2. Environmental compliance: 5G water quality monitoring system will be deployed, the wastewater treatment efficiency will be increased by 40%, and the COD emission concentration will be lower than the national standard by 50%.

Construction site pictureXinhanze

Full-cycle worry-free service

01

Professional answers to customer inquiries

7*24 hours online service

02

Tailored Solutions

Solution within 2 hours

03

Assist in the preparation of construction plans

12 hours to the customer site

04

Guide installation and commissioning

Resolve operational issues within 24 hours

Selected field cases

Carbon nanotube purification production line

-

Fujian, China

-

Anode Materials for Sodium Batteries

Overseas project site

-

Indonesia

-

Unknown

Recycled negative material purification production line

-

Anhui, China

-

Recycled negative material

Expandable graphite production line

-

China

-

expandable graphite

Natural purification production line

-

China

-

natural graphite

Sodium-Hard Carbon Purification Line

-

Fujian, China

-

nano battery

automatic control system

-

China

-

Unknown

porous carbonic acid washing production line

-

China

-

porous carbonic acid washing

Quartz sand pickling production line

-

China

-

Quartz sand pickling

PPH Equipment

-

China

-

PP Equipment