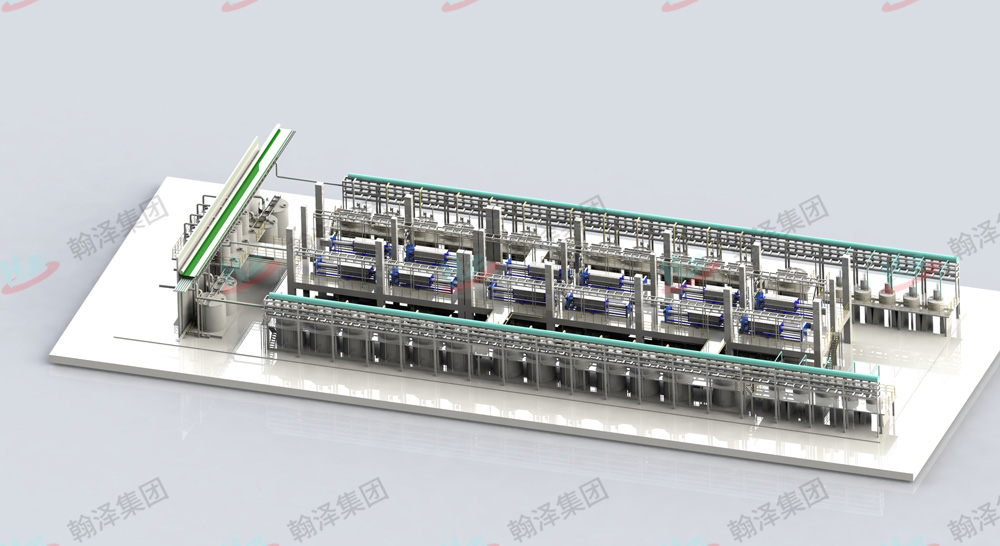

Production line introductionXinhanze

There are usually raw material silos for storing porous carbon raw materials to be processed, and the raw materials are transported to the pretreatment link through belt conveyors, screw conveyors and other equipment.

Pretreatment

Including crushing, screening and other steps, so that the porous carbon raw material to achieve a suitable particle size, so that the acid in the subsequent pickling process can fully contact the raw material, improve the pickling effect.

pickling reaction

This is the core link, the general use of acid-resistant reactor. Put the pretreated porous carbon into a reaction kettle, add an appropriate amount of acid, such as hydrochloric acid, sulfuric acid or hydrofluoric acid, and stir evenly. At the same time, the reaction temperature is controlled in a suitable range by a heating device and a temperature control system, for example, the temperature is usually controlled in the range of 50 - 80 ° C. during hydrochloric acid pickling. Reaction for a period of time, so that the acid and porous carbon impurities in the full reaction, the impurities are dissolved and removed.

Acid recovery and recycling

After the pickling reaction is completed, the acid solution is separated from the porous carbon by filtration or centrifugation. Part of the acid can be recycled back to the pickling reactor after treatment to continue to use, in order to reduce production costs and reduce acid discharge.

Water washing and neutralization

The porous carbon after acid separation needs to be rinsed with plenty of water to remove residual acid and dissolved impurities until the pH of the rinse water is close to neutral. Sometimes, neutralization treatment is carried out, and the trace acid is further neutralized with an alkaline solution such as sodium hydroxide.

Dehydration and Drying

The porous carbon after washing contains a large amount of water, and the water content is reduced by mechanical dehydration through filter press, centrifuge and other equipment. Then it is sent to drying equipment, such as vertical dryer, rotary kiln dryer, etc., and dried at a certain temperature to remove the remaining moisture to obtain the pickled porous carbon product.

Packaging and storage

The dried porous carbon products are tested for quality, such as iodine adsorption value, methylene blue adsorption capacity and COD removal rate, and then packaged and stored in the warehouse for shipment.

Pretreatment

Including crushing, screening and other steps, so that the porous carbon raw material to achieve a suitable particle size, so that the acid in the subsequent pickling process can fully contact the raw material, improve the pickling effect.

pickling reaction

This is the core link, the general use of acid-resistant reactor. Put the pretreated porous carbon into a reaction kettle, add an appropriate amount of acid, such as hydrochloric acid, sulfuric acid or hydrofluoric acid, and stir evenly. At the same time, the reaction temperature is controlled in a suitable range by a heating device and a temperature control system, for example, the temperature is usually controlled in the range of 50 - 80 ° C. during hydrochloric acid pickling. Reaction for a period of time, so that the acid and porous carbon impurities in the full reaction, the impurities are dissolved and removed.

Acid recovery and recycling

After the pickling reaction is completed, the acid solution is separated from the porous carbon by filtration or centrifugation. Part of the acid can be recycled back to the pickling reactor after treatment to continue to use, in order to reduce production costs and reduce acid discharge.

Water washing and neutralization

The porous carbon after acid separation needs to be rinsed with plenty of water to remove residual acid and dissolved impurities until the pH of the rinse water is close to neutral. Sometimes, neutralization treatment is carried out, and the trace acid is further neutralized with an alkaline solution such as sodium hydroxide.

Dehydration and Drying

The porous carbon after washing contains a large amount of water, and the water content is reduced by mechanical dehydration through filter press, centrifuge and other equipment. Then it is sent to drying equipment, such as vertical dryer, rotary kiln dryer, etc., and dried at a certain temperature to remove the remaining moisture to obtain the pickled porous carbon product.

Packaging and storage

The dried porous carbon products are tested for quality, such as iodine adsorption value, methylene blue adsorption capacity and COD removal rate, and then packaged and stored in the warehouse for shipment.

Selected field cases

Carbon nanotube purification production line

Fujian, China

Anode Materials for Sodium Batteries

Overseas project site

Indonesia

Unknown

Recycled negative material purification production line

Anhui, China

Recycled negative material

Expandable graphite production line

China

expandable graphite

Natural purification production line

China

natural graphite

Sodium-Hard Carbon Purification Line

Fujian, China

nano battery

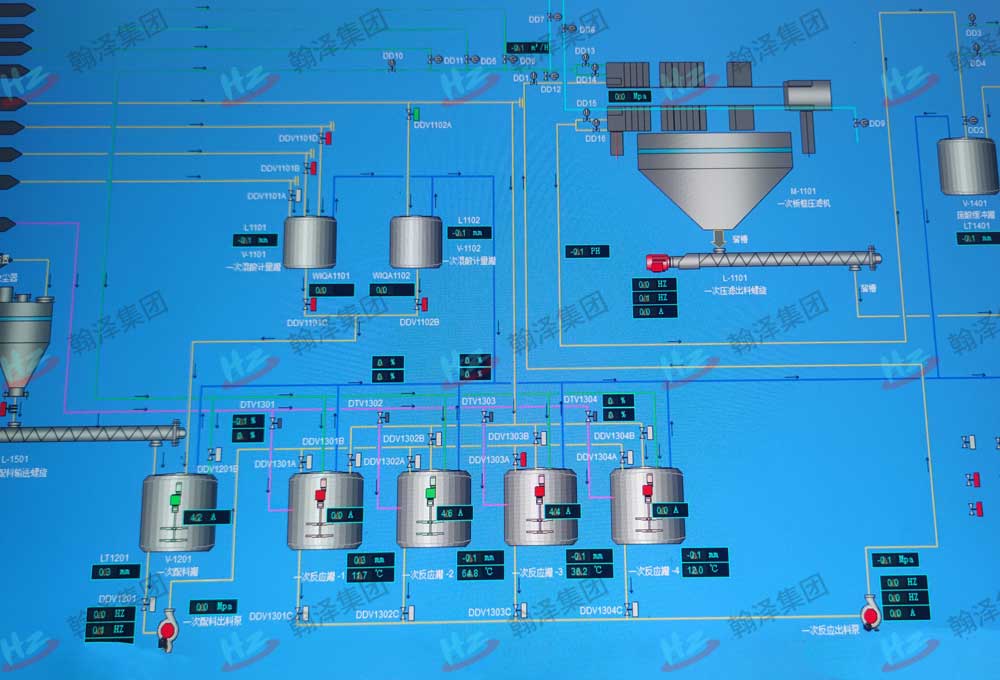

automatic control system

China

Unknown

porous carbonic acid washing production line

China

porous carbonic acid washing

Quartz sand pickling production line

China

Quartz sand pickling

PPH Equipment

China

PP Equipment