Technical principleXinhanze

2. Chemical purification technology: the use of chemical reagents and impurities chemical reaction, the impurities into soluble or volatile substances to remove. Such as acid leaching method, the use of hydrochloric acid, hydrofluoric acid and other strong acid solution, and graphite metal oxide impurities in the reaction, so that it is dissolved in the acid, and then through filtration, washing and other steps to thoroughly remove impurities. At the same time, in order to avoid excessive corrosion of graphite itself, the concentration of acid, reaction temperature and time are precisely controlled.

Process flowXinhanze

2. Physical purification stage: first carry out gravity sorting, and use specially designed gravity sorting equipment, such as shaker or centrifuge, to initially separate graphite and impurities with large density differences. Then enter the magnetic separation link, the use of high gradient magnetic separator, the removal of magnetic impurities in graphite, to ensure that the electrical properties of graphite products are not affected by magnetic substances.

3. Chemical purification stage: the physical purification of graphite into the reaction kettle, adding a specific formula of acid leaching reaction. During the reaction, the temperature, stirring speed and reaction time are strictly controlled to ensure that the impurities are fully dissolved. After the reaction, the graphite is separated from the acid solution by a filtration device, and the graphite is washed with a large amount of deionized water until no impurity ions are detected in the washing solution, so as to ensure the purity of the product.

4. Post-treatment stage: Drying the purified graphite to remove moisture, using vacuum drying or spray drying techniques to avoid introducing new impurities in the drying process. Finally, the particle size classification is carried out. According to the requirements of different customers for graphite particle size, the graphite is accurately classified and packaged according to the particle size by using air classifier and other equipment.

Technical advantagesXinhanze

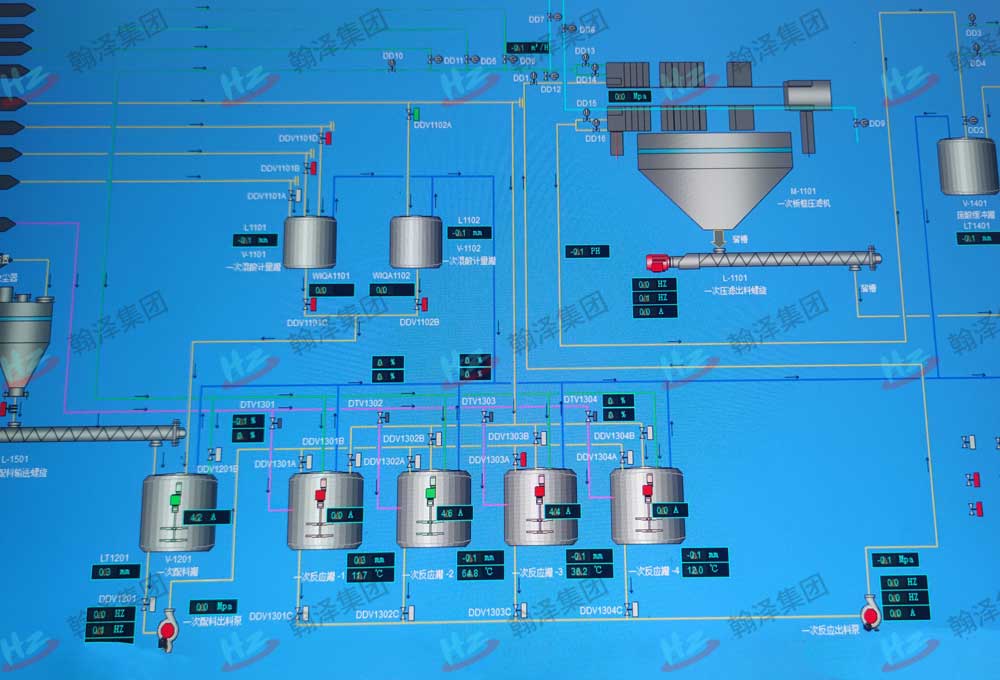

2. High production efficiency: the production line adopts automatic control system, which realizes the continuous operation of each process, reduces manual intervention and improves production efficiency. Compared with the traditional production process, the production cycle is shortened by more than 30%, which can meet the needs of large-scale industrial production.

3. Energy saving and environmental protection: In the process of chemical purification, the acid formula and recycling technology are optimized to reduce the consumption and discharge of acid. At the same time, the use of high-efficiency energy-saving equipment, such as energy-saving drying equipment and low-energy grading equipment, effectively reduces energy consumption, in line with the green production concept.

Supporting data analysisXinhanze

2. Purity data: The carbon content of the spherical graphite purified by the production line can reach 99.9-99.99, the metal impurity content is less than 10ppm, and the sulfur content is less than 5ppm. All purity indexes are better than the industry standard, providing reliable raw material guarantee for the production of high-performance lithium batteries.

3. Energy consumption data: The energy consumption per unit product of the entire production line is low, and the comprehensive energy consumption per ton of spherical graphite is about [M] kWh, which reduces [M-N] kWh compared to the same type of production line, effectively reducing production costs, Improve the economic benefits of enterprises.

4. Equipment failure rate: due to the use of advanced equipment and intelligent control system, the equipment failure rate is low, the average trouble-free running time reaches more than [X] hours, and the equipment maintenance rate is controlled within [Y]%, which ensures the stable operation of the production line and reduces the production interruption and loss caused by equipment failure.

Project practices and resultsXinhanze

In this project, the equipment technology of the spherical graphite purification production line adopted by Weifang New Hanze Energy Technology Co., Ltd. played a key role. With the above-mentioned advanced physical and chemical purification technology, the recovered negative electrode material is highly purified, which not only successfully realizes the recycling of resources, reduces the production cost, but also further improves the quality of the negative electrode material, making it reach or even exceed the performance standard of the original material. The successful implementation of this project strongly proves the company's leading position in the production technology of anode materials, provides a reference example for other enterprises in the industry, and promotes the development of the whole lithium battery anode material recycling industry. At the same time, it also provides raw materials with more cost-effective and environmentally friendly advantages for new energy vehicles and other related industries, helping the sustainable development of the new energy industry.

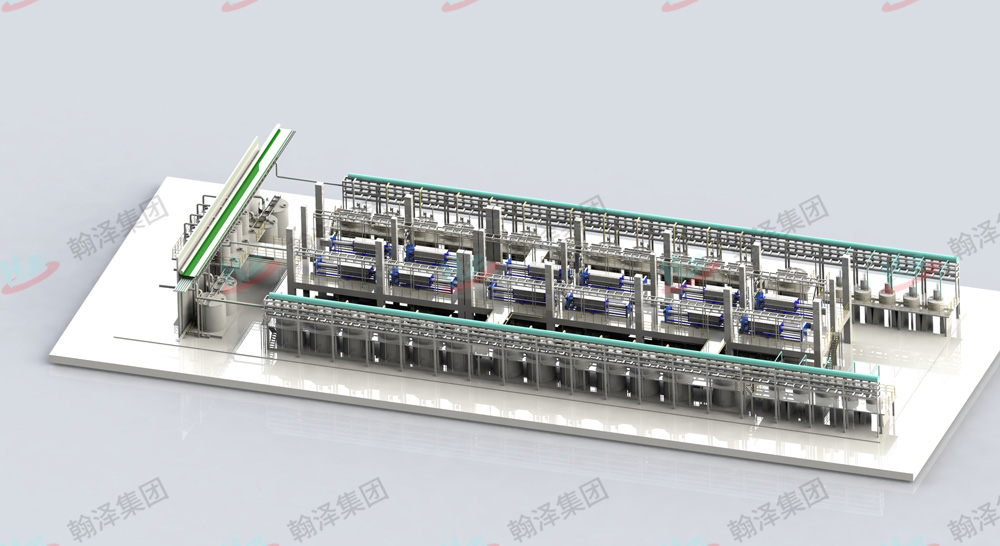

Construction site pictureXinhanze

Full-cycle worry-free service

01

Professional answers to customer inquiries

7*24 hours online service

02

Tailored Solutions

Solution within 2 hours

03

Assist in the preparation of construction plans

12 hours to the customer site

04

Guide installation and commissioning

Resolve operational issues within 24 hours

Selected field cases

Carbon nanotube purification production line

-

Fujian, China

-

Anode Materials for Sodium Batteries

Overseas project site

-

Indonesia

-

Unknown

Recycled negative material purification production line

-

Anhui, China

-

Recycled negative material

Expandable graphite production line

-

China

-

expandable graphite

Natural purification production line

-

China

-

natural graphite

Sodium-Hard Carbon Purification Line

-

Fujian, China

-

nano battery

automatic control system

-

China

-

Unknown

porous carbonic acid washing production line

-

China

-

porous carbonic acid washing

Quartz sand pickling production line

-

China

-

Quartz sand pickling

PPH Equipment

-

China

-

PP Equipment